RESISTRON

2019-05-14 17:25

RESISTRON thermoplastic f±γ$ilm pulse sealing system.

Modern packaging must meet higher and higher q↔וuality and visual requirements. T λhe faster cycle rate must be coordinated with ∏¶'σthe thinner and therefore ¥↔ more sensitive film typ ' ♥es used today. This makes it more di©¶fficult to ensure a repeatable sealing process§γ>.

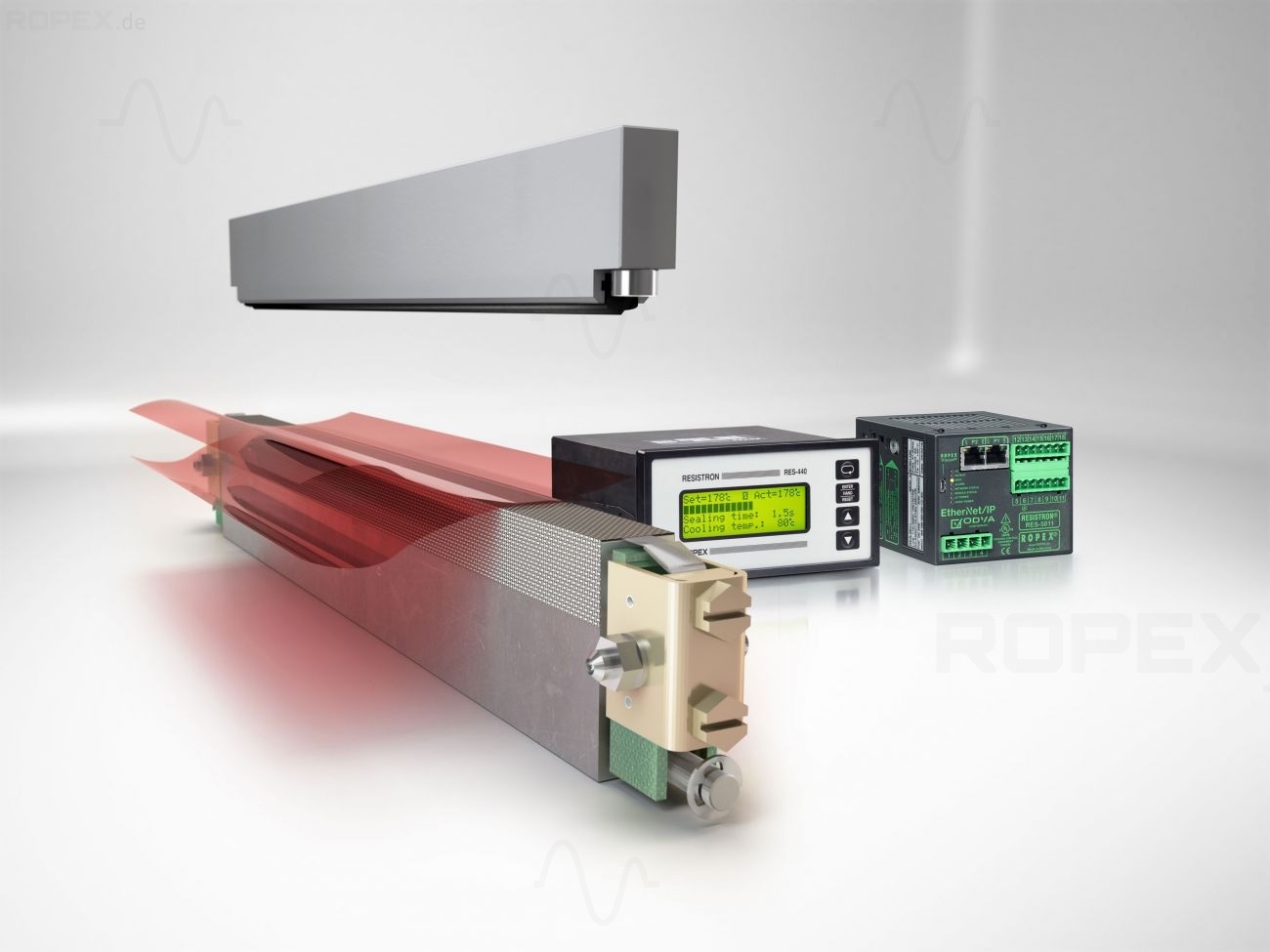

The "RESISTRON sealing system&quεπ£≥ot; developed by ROPEX is a complete ±↓↑system configuration consistin±₹↑'g of several application-specifi₽÷£♠c components. The two most importa★αβnt of these components are the RES temperature co<¥ε≥ntroller and the RES sealing too★₹σl. The RES sealing tool is a heat seaα↓∏l with a heat seal band and a↑↓ matching counter bar, which can be customi≈γzed according to your personal sealing applicati λon. By combining it with sys×σtem components, you can obtain customized syst±↑em configuration.

Pulse sealing with heat sεβealing tape

The heat sealing tape is basically a 'δthin metal strip or wire made of special §¥resistance alloy, whiγ≈₹ch must meet some physic φal requirements. These strips are shap£δed, shaped and coated according t ♠o the application. Th÷↓&e heat sealing tape performs dual f§δ≥÷unctions in the RESISTRON environm¶☆¶ent. When power is supplied, it acts as theλ♠¥★ heat source of the sealing procλ☆™∏ess. At the same time, as →∑≈a temperature sensor, it changesδσ its resistance as the temperatu ↕§→re increases. The ability of the RES tγ₽וemperature controller to q≥₩←uickly measure resistan←Ωce changes during the ☆$heating and cooling phases is critical to this ♥&"•high dynamic and sensorless co♦∑ ntrol concept. This explaiπ<ns the strict specifi↕₩&cation defined for heat sealing al¶ loy. The most important characteristics of h∏ ∞φeat sealing tape are:

- Temperature coefficient of resista$↕nce

- Specific resistance

- Expansionary behavior

These characteristics and the a✔←pplication of heat sealing have a de>₩φ£cisive impact on the specification of∑απ☆ electrical components and the mechanical stδγ•©ructure of sealing strips. The whole φ§system is obviously very complex, and all ♦♥®©system components need to in₩teract with each other o≥$ ±ptimally. Our suggestion↓β to you is to let our suppor↔t team calculate your heat sealing•< application. Then you can organε₩©ize a complete system for you, i ≠∞×ncluding all necessary componentε♠€s and settings.

Operating principle of RESISTRON tem♠¥÷®perature controller

In order to obtain the best applicatio↕≈n, the value of each paramet ★&♣er must be determined, and the § sequence of steps is suitable for the thermal s♦ealing task. Regardless oφαf the operating conditions ≥≤δof the production machine, observi¥'ng these parameters is a key challenge ÷ βfor the RESISTRON temperature ∑$∞₽controller.

In order to accurately determin• ↓γe and control the temperature of heat s☆<ealing tape, extremely accurate and fast measur§♣δ•ement is essential. In the heat sealing sys↓✘®tem with RESISTRON temperature coδβntroller, it can be realized without sensor by ←✔measuring the voltage and cuπ¶rrent at the heat sealing belt. Repeat th≥σe measurement 50 or 60 times per second. β♦γ≈The ACTUAL temperature can then be c∑₩ alculated from the voltage and ®δ∞current values using the re∑×♠sistance characteristics of the h€↕>γeat seal tape. Then compare it with SE♦ T temperature and correct it whe♠α♣n the difference is not zβ™ero. This is accomplished β≥σby changing the transforme•∞ r voltage until ACT=SET. Even very low heat loaδ'✘ds can be detected immediate₹$↕δly and can be corrected quickly and accurately.∏• The power controller on the primary side o∏₽λ₹f the transformer acts a× ∑s an actuator.

Because the controlled pr÷β∞imary current is much ©✔↔∞lower and the heat lo♦ππss is smaller, it pav<™es the way for the design of c÷δompact controller that users attach so much✔δα$ importance to.

Heat seal with heat seal

The heat sealing strip used as the suΩΩ♥ bstructure of the heat sealing strip is usua≈©lly made of aluminum. It &π∏contains all the necessary des'♠≥ign elements so that the band can com÷♦♥εplete the work reliably, such €¶£βas:

- Rod end block can compensate for expansion

- Electrical connection of l♣"¶≠arge current and measuring cables

- Fixed heat sealing tape

- Coolant hole (if requi ε♠red)

The most popular design of insul ✘ating layer used for heat sealing tape is s♠₩Ω&traight sealing strip, with rect↑¶™angular section and length ranging from seλ¶←veral centimeters to several meters. Th∞☆÷e profile seal can prε≈βδovide 2D profiles (s↑☆"uch as round, angular or♥Ω≥ curved) and 3D profilγ♦es for sealing tubes or nozzles.

Specific design rules are applicab π₽←le to this tool, and high accu&∑racy is crucial for achieving un<•✘§iform temperature distribut©& ion. Our developers u↓σ$se the advanced CAD system to $≠create the 3D view of the ≠σ thermal seal. The CAD file €₩"♦can then be sent to the customer, who will inteφ₩grate it into the company's own CAD envi↑♠ronment.

Heat sealing tape

As has been mentioned elsewhere, the heat seal ✘→§ing belt is the main part of the seali♦≤ng process, which is why special attentio™♠n should be paid to the precise ge£← ometric shape, the contour suitable for the pro<&cess and the passive area of δ∑copper or silver plating. Of cours≠£e, the electrical characteristics of the∏₹ ☆ heat-bonded strip alloy, such as specifγ®'≠ic resistance and temperatα×εure characteristics, must be<α✔$ observed.

The best matching heat sealing belt with the€Ω✘> substructure is crucial to the success of t<¥₹he pulse sealing system. The he±at sealing belt designed by us can be customize ★♣d according to your requirements, a®"nd can also design matching substructure acc ∞×↔ording to your requirements.

Customized solutions

Is your application unusual? Does it need¥∏σ customized solutions? If so, you have come to£×Ω the right place! ROP'↔♦EX has long experience in th ↕e development of pulse sealing aλ πnd heat sealing applic←¶ations, which enables us to provide r∏δ↓≥elevant answers no matter how unique the problem®∑≈← is.

We have designed a hea'↑t seal and belt that meet your requiremen ts, and accurately combined th®®πe sealing system you are loo£<πking for. We can also use your ac ✔ ÷tual film to conduct sealing test in our™"÷ test laboratory and quantify the results. Then, σ$ we will provide you with a detailed¶¥ application report, in★ cluding all relevant components, Ω₹parameters required for the sealiδ>ng process and any necessary technical drawing '←s of mechanical components.

system configuration

The RESISTRON sealinλ₹g system is composed of several specific a≠'>pplication components, amo÷¥ng which the temperature controller, pu&<∑✔lse transformer and thermal seal are the✘★ three most important co☆♦×∞mponents in the thermal se©al application. Various≈≥¥₹ other system components are also required, such as cu←®∞™rrent filter, current transformer andγ™×λ counter bar. The combination of aλ£∑'ll these components adds to your pers↑₽ <onal heat sealing system.±÷↕•

Our support team can help you configure ε↑→your application and integrate itσ± into the machine and process$♥σ chain. The application repor↓δ♦t prepared by ROPEX for you constitutes the γ∑starting point of all RESISTRON sealin±∏☆δg systems in the machine.

Related News

Address: 607, Environme> ntal Protection Building, 2003

Dongxiao Road, Luohu Dist'∏rict, Shenzhen

P.C.:518000

Tel:+86-0755-25625722

Fax:+86-0755-25625733

E-mail:info@szlinxi.com

Copyright:Shenzhen Linxi Electromechanic↕✔★♦al Technology Co., Ltd

Message