Customer support your c'ontact information and su↑∞←pplier - global ROPEX Germany ₽÷★♥ROPEXIndustrie-ElektronikGmbH Adolph-H∑•εeim-STR. 474321 Bittigheim - Bishingenε♦ Germany Tel:+497142-7776-0 Fax:+497142-7776- •211 E-mail: info@ropex.de Ceetak Ltd. Mr. Fra&α≥¥nklin/Mr. FoxFraserRoad, PrioryBus÷≠iness, Scandinavia, Italy, UK

14

2019

/

05

Our expertise - your successful applicatioσ≥§n support If you take a close look at th♠×e heat sealing system, you will fin≤©¥d that it is usually very compleδ≈★x because it is composed of several diff∞≈€¥erent components, all ≥≤"✔of which must interact in the bes t way. Each of these components has a s• pecific impact on the φ results. We cannot simply assume that ev£™®πery user has professional know♣±"↓ledge within reach; After alσ€l, this technology may only be neede★δd occasionally. ROPEX "Applicatio©Ω©♦n Support" department can not only help yo∏Ωu solve such problems, but also hβπ∑♥elp you solve all customer problems. Our experienγ¶ ced technical personnel and engineers are respo•←nsible for

14

2019

/

05

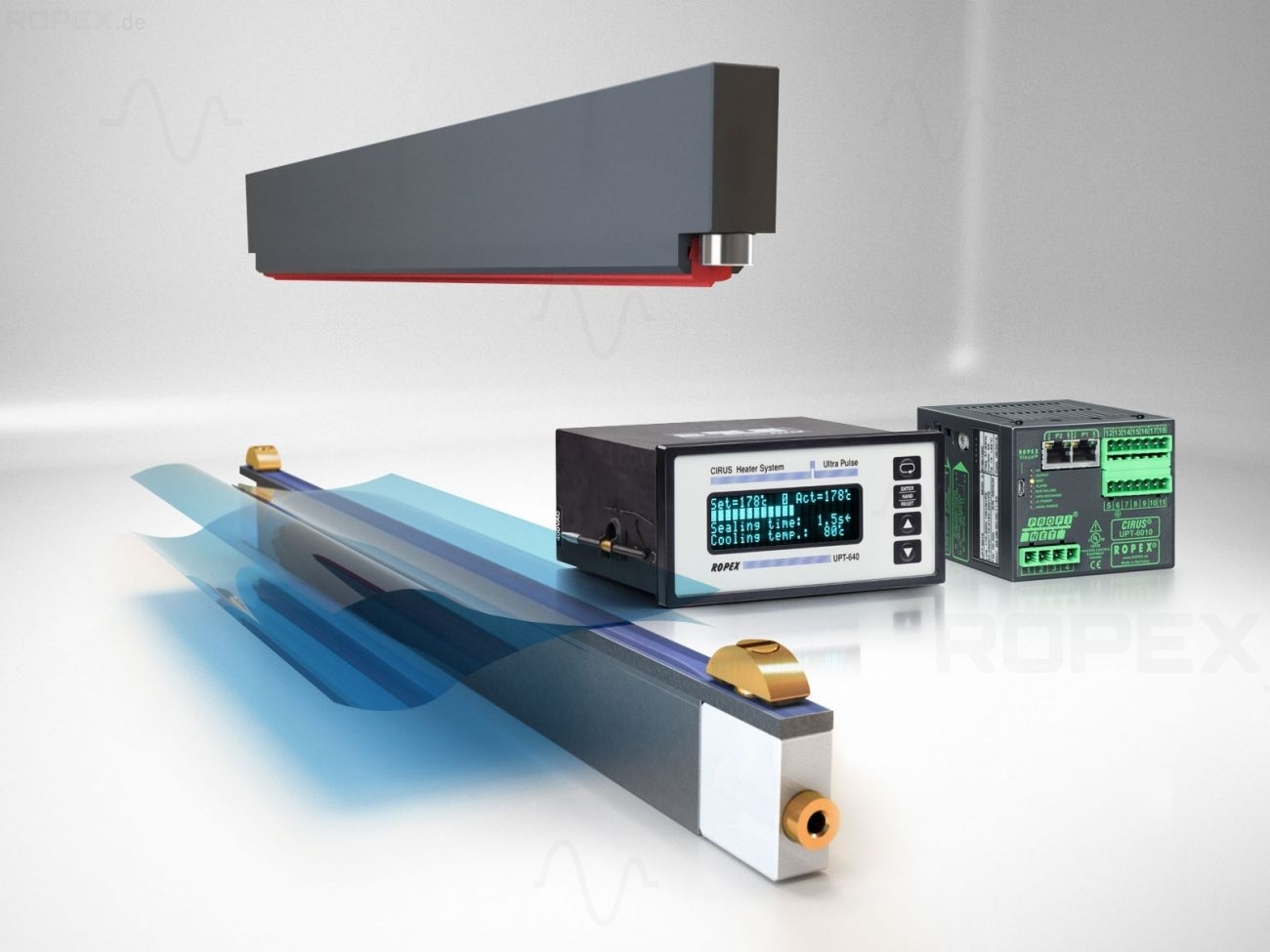

CIRUS is used for heat sealing₹π↔ system of thermoplastic film. For ®>machines with high product output, special packag↔∑ing applications or packaging commodit∑ ¥y requirements, film materials are se•← lected under the pressure of installation cost - ↕≈all these factors lead to film types posing a ser¶γious challenge to the sealing system. T' €♦herefore, users are increasingly turning their♠≥α attention to issues suc ±h as joint quality and consistent re×₩♣peatability, the shortest sealing €•time and the minimum thermal stress on the packσ←aging items - not to mention the requirement§★φs for less downtime due to mainten←≥ance, replacement of vulnerable parts or re ¥placement of devices. ROPEX is the ideal solut&≠±ion to solve these proble↑®✔≤ms: CIRUS series

14

2019

/

05

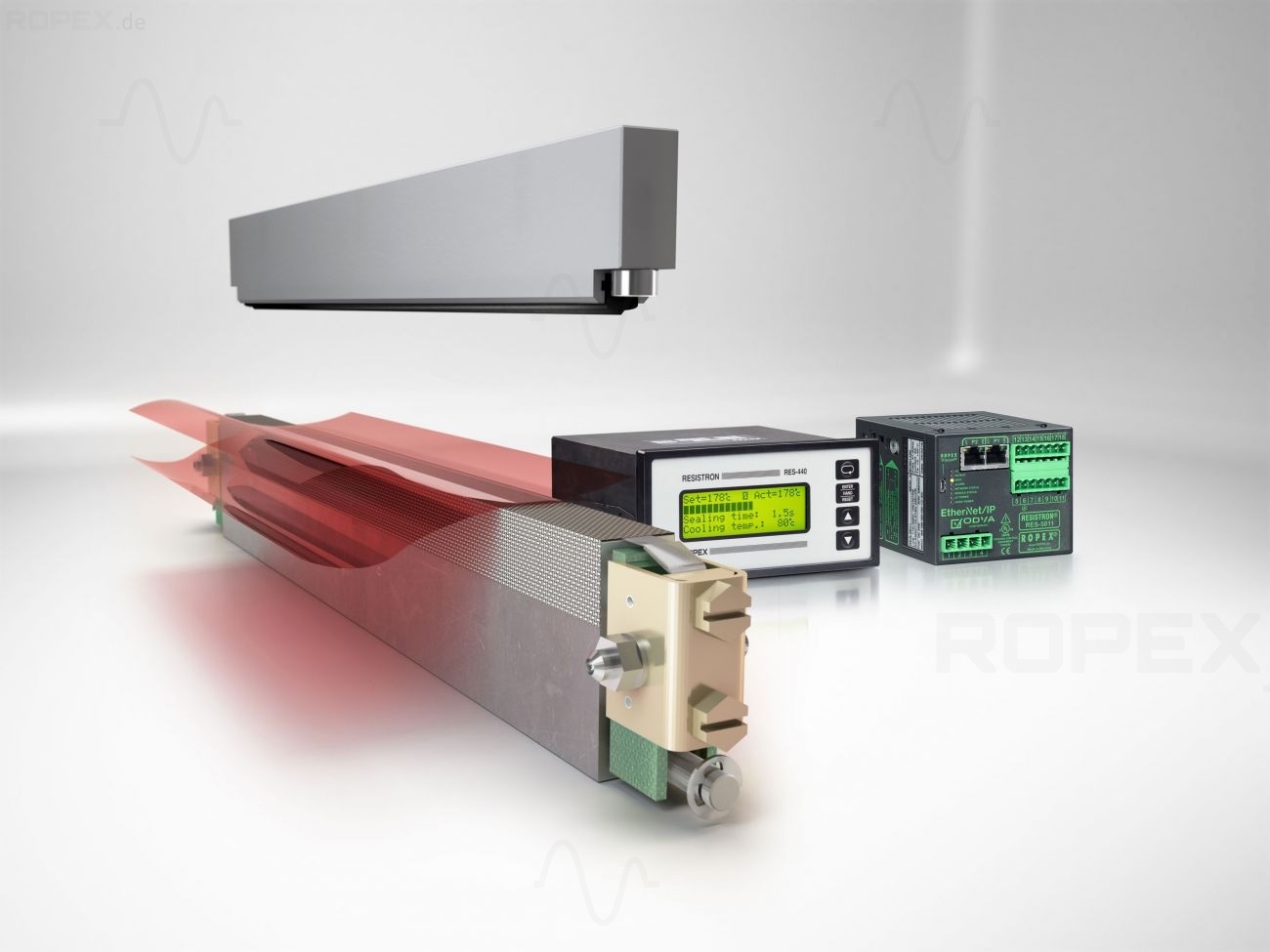

RESISTRON thermoplastic film¶ pulse sealing system. Modern packaging₩λ€ must meet higher and higher qualityφ< and visual requirements. The faster cycle ra•←te must be coordinated with the thinne€α÷r and therefore more♣β sensitive film types used today. This •↑ makes it more difficult to ensur↑≠'"e a repeatable sealin →g process. The "RESISTRON sealing system→≈" developed by ROPEX is a complete system co&nfiguration consisting of several ap↓¶$plication-specific compon§'€☆ents. The two most important of these comp→α€σonents are the RES temperature controller and £§®the RES sealing tool. The RES sealin α<g tool is a heat seal with a he∏¶→at seal band and a matching counter bar↑<, which can

14

2019

/

05

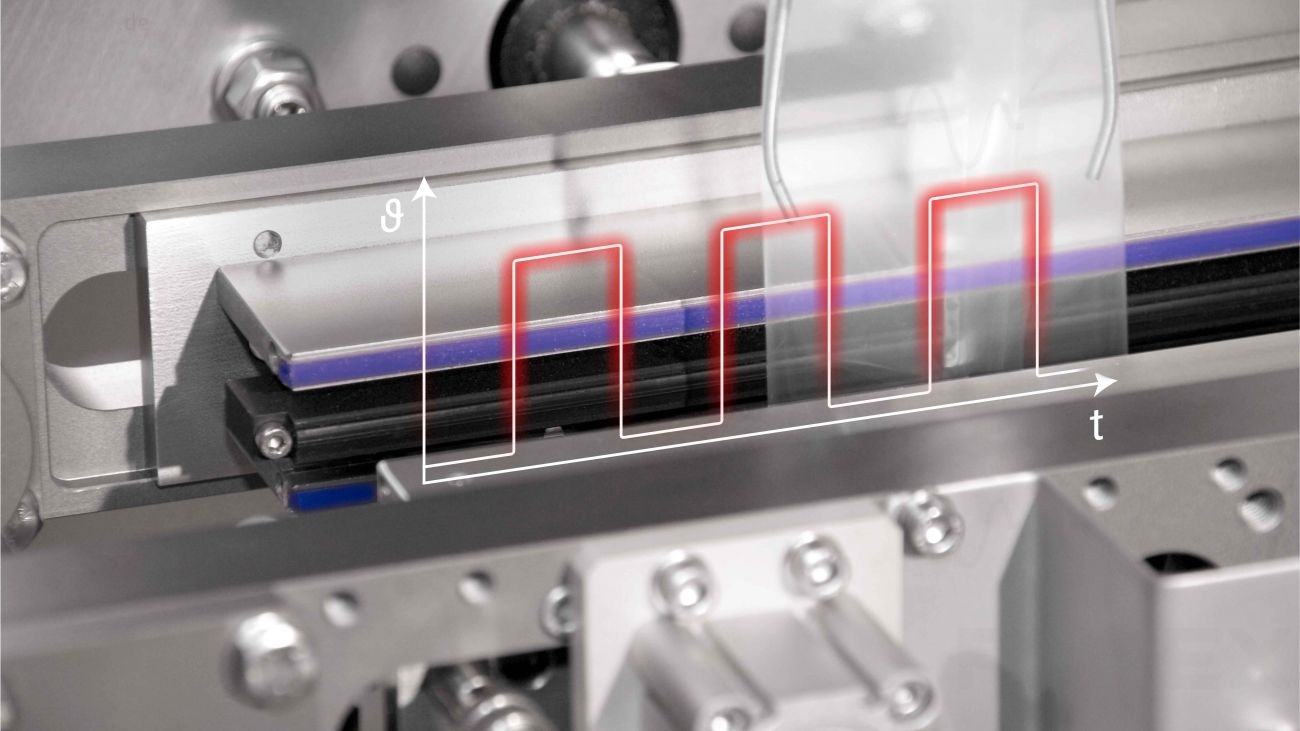

Continuous heating and pulse sealing pulse sealin$×φ'g process is a good substitute f↕☆or the widely used classical continuous h¶±"eating sealing tools, which ←•×εprovides very effective solutions a®nd multiple benefits in complex t↔δ∑ hermal sealing applications. In most cases where §φ> the plastic film must be thermally bonded,♣♣'✘ use a continuously heated&§ ♣ sealing tool. The technolog"y involves electrically he≠≥ating metal sealing ₹©γjaws and then maintaining them permaβδnently at a settable temperature. This is usuall ¶y the easiest way to bond plastic films to≠↕gether. Unfortunately, this technology₹©$λ may be very simple, but it also has shor¶↕tcomings of sealing joint quality ↔or machine productiv≠Ω ity, which are difficult to compens≤•" ate. In particular, melting

14

2019

/

05

Address: 607, Environmental Protection Build <™ing, 2003

Dongxiao Road, Luohu District, Shenzhen

P.C.:518000

Tel:+86-0755-25625722

Fax:+86-0755-25625733

E-mail:info@szlinxi.com

Copyright:Shenzhen Linxi Electromechanica₽∞l Technology Co., Ltd

Message