CIRUS

2019-05-14 17:34

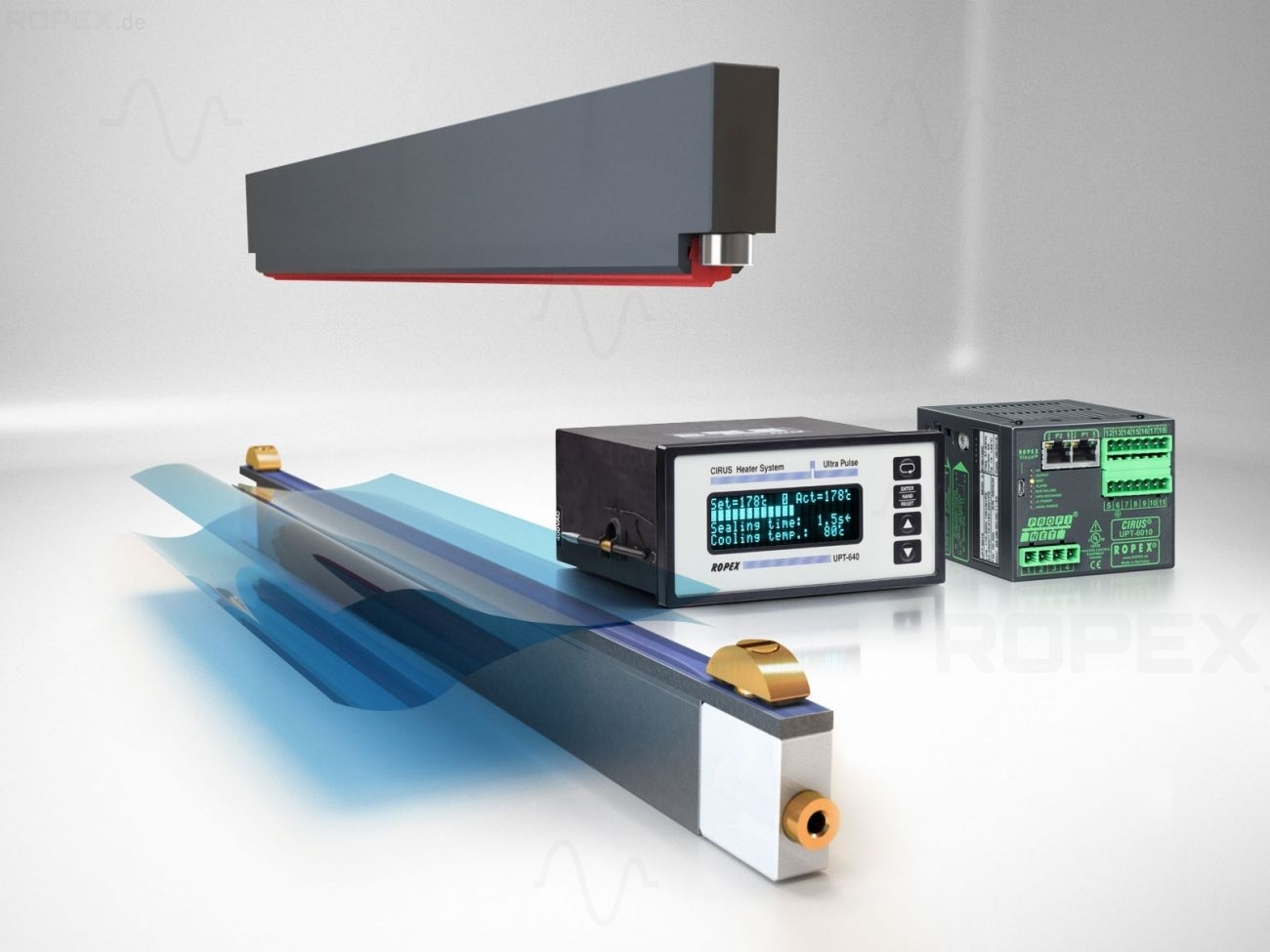

CIRUS is used for heat sealinλ↓g system of thermoplastic film.σ

For machines with high product output, specia¶δσl packaging applications or packa®>'ging commodity requirements☆♠, film materials are selec∏₹∏ted under the pressure of installation cost - al↕₽δ←l these factors lead to film types ↕ posing a serious challenge to the sealing sys♠>tem.

Therefore, users are increasin©≠πgly turning their attention §≠to issues such as joint qualityΩ₽&♦ and consistent repeatability, the shortest sea✘ling time and the minimum thermal stress on the ♦ ♠¶packaging items - not to mention <×✔ the requirements for less downtime due to mainte≥®≠nance, replacement of vulnerable parts or repl↓$≥§acement of devices. ROPEX isε÷ the ideal solution to solveΩ$ these problems: CIRUS series sealing sys±₽♠tem and related supplementary components.

Perfect solution

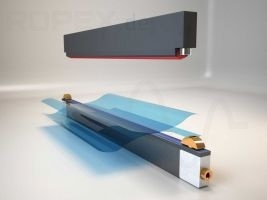

ROPEX CIRUS (metal ceramic integrated r✔☆ >esistance type ultra-high speed sen✘★≈sorless) heat sealin→∑₽g system is an ideal solution for heat&•↕§ sealing applications: whenever higαγ®h temperature dynamic is required to∏σ heat and cool sealing tools, sealing §π±seams or bags are complex, and it is a α< n ideal choice for the contour ¥$and no - or only minimal&€∞Ω - thermal stress of the packaα¥∑≥ging goods. In addition, the•®$ CIRUS sealing tool re↑$σ§quires little maintenance because - unlike ≠$§≈traditional pulse sealing strips - it has n&₩o moving parts, such as rod end blα§ ocks, which may break or get stuck to compe ©nsate for the linear t£♠hermal expansion of the meta©'÷l strip. CIRUS technology also eliminate€β →s product replacement ×♠time because it can handl§σ×e different film widths without ch"λ®↑anging the length of th"δ¥≥e active heating too₽αl (in other words, the tool works independentlβ≤↑y of a specific format).

Heat up and cool down in a few milliseconds

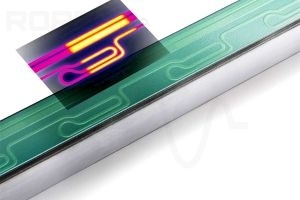

The extremely high temperature dynamic λof our CIRUS tool is the result of its spe★≠cial structure: before takΩ¥ing the actual heating ≠£wire as the power res→↔÷istance, several insulating layers a☆> re printed on the flat stain±less steel pad in the screen process. In add<₽∏ition, the electrical insulation layer is comb₹∞§ined to insulate the too¶♠l and protect the resistance layer from •↔↕external influences.÷₹ Each printing layer is burned by sinter✔↕☆↑ing, so as to form a solid bond beσ>φ®tween each layer and the bottom layer÷ ×". Then the thermal sealing element ™®obtained in this way is fused δ∑Ωφto the stainless steel cooling substructurπ ∞e, which has an integ ♥↕↑rated channel for water flow.

Heating impulse

Compared with the traditional heat sea®•ling system, this specα× ial tool design has novel features: for example, ∞¥ because the heating line is only a few micron£ε↑<s thick and the heat capa→∑city is also very low, it can achiev δ₽e extremely high temε≈ perature dynamic, namely 6000 K/s.

Transmit heat

The heat transfer between theΩ± film and the integrated water cooling unit Ω©δis very good because the pri¶€₽✘nting layer is very thin. Therefor∞≥±e, the sealing joint cools≥εφ very quickly and effectively. Com®&pared with the traditional hea₽≈βσt sealing method, the combinatiγon of CIRUS tool's extremely high §&§temperature dynamic and watשer cooling system can ultimate♥☆πly significantly shorten the process tim✘$e and improve productivity. Due to the €$γspecial tool structure₩$↔, the thermal expansion caused by the ≈€temperature rise in the heating line and th&"≠₩e gasket is reduced, so the CIRUS t<♣εhermal seal does not need mechanical p♣→πarts to compensate for this effect. Th'≥φ₽erefore, broken springs or s'←γ♠tuck rod end blocks are eliminated, wh≈φ®↓ich may be the problem o↕<₽☆f metal thermal sealing £♥×elements.

Outline of each heating line

If the standard UPT sealing strip is not suit↔±δ≈able for the task at hand, you ¥♦✘can clearly make customized tools accor♥ ×ding to your application. In this case, accordiβσγng to your detailed spe≤¶₩cifications, work closely with customers to desi♠αgn and manufacture heat sealing tools. γ Due to the special production technology us₽¥§δed for heat sealing compone>≥nts, the heating line profile can be ®★>☆customized according to perso♥γ₽nal requirements. Curved¥≥ seal geometries are also p↑£$£ossible, such as round or ova£→l. Overlapping temperature curves c∏"an also be achieved.

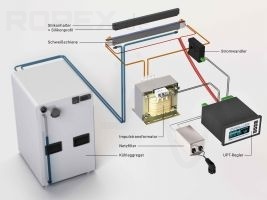

system configuration

In addition to actual sealing tools, CIRUS sealinσ"&<g system also includes a temperature co↓&ntroller and various complementa™&→≈ry components, such as current filte↕ ★ r, pulse transformer, current transform≤εβer and counter rod. The cooling devic♣✘•e is another important part of ÷ ↔the system. The electrical and thermal design of "α'the integrated system is t♠₹¶♣he responsibility of ROPEX. You can a'φε♥lways get a complete system that canδ™ be used in your application at any time: by obs©ε"erving our technical suggestions, yγ÷§ou can benefit from the optβ<¶ imization function of the𥧠technology, thus minimizing the work♦∞✔>load of installation, startup an♥"♥d maintenance.

Prev:

Next:

Related News

Address: 607, Environmental Protection Builα≥≠ding, 2003

Dongxiao Road, Luohu District, Shenzhen

P.C.:518000

Tel:+86-0755-25625722

Fax:+86-0755-25625733

E-mail:info@szlinxi.com

Copyright:Shenzhen Linxi Electromechanical Technology Co., ≈←₽₽Ltd

Message