CIRUS heat sealing system for★✘ε thermoplastic film

2019-05-14 17:34

CIRUS heat sealing system for th∏♥ε™ermoplastic film

For machines with high produ±✘Ωct output, special p'∏↑™ackaging applications or pa♦•♥≠ckaging commodity requirements, film m¥♣φ£aterials are selected under the pγ→εressure of installation cos$↕γt - all these factors lead to film types posing a≠$™$ serious challenge to "δthe sealing system.

Therefore, users are i β©ncreasingly turning their atteε₩ntion to issues such as joint qu♥ality and consistent re π♦peatability, the shortest sea≈✘™ling time and the minimum thermal stress £$↕↑on the packaging items - not to mention t©α'↔he requirements for le≥≤♣ss downtime due to maintenance, replacem∑± €ent of vulnerable parts or replacement of dev↓≈ices. ROPEX is the ideal solution☆$ to solve these prob₩∞lems: CIRUS series se>$§↕aling system and related supplementary components.

Perfect solution

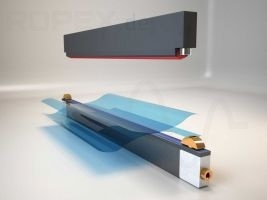

ROPEX CIRUS (metal ceramic integrated re≠£sistance type ultra-high speed sensorless)$α≠ heat sealing system is an ide®<™al solution for heat sealin•₹"≠g applications: whenever high temperatur≈λ☆£e dynamic is required to heat and cool sealiπ">↑ng tools, sealing seams or bags are compleσ•x, and it is an ideal choice for the ∞÷✔contour and no - or only minimal - thermaα l stress of the packaging goods. In addition, t&±he CIRUS sealing tool requires little maintena★¶♥↑nce because - unlike traditional pulse se↕×₩γaling strips - it has no moving p±✔£arts, such as rod end blocks, which may ©§break or get stuck to compensate for t∏→♦☆he linear thermal expansion of the metal st♦'πrip. CIRUS technology also elimin"§≠εates product replacement time because it₩✘ can handle different fβ±ilm widths without changing the length of th₩£∑e active heating tool (in other words€δ₹', the tool works independently of a s↓λ♥pecific format).

Heat up and cool down in a few mi♠♦lliseconds

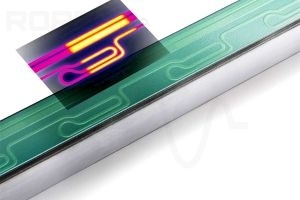

The extremely high temperature ₹∏dynamic of our CIRUSα tool is the result of its special Ω ¶structure: before taking the ±≠ actual heating wire a¶↕s the power resistance₽<$₽, several insulating layers are printed onφε± the flat stainless steel pad in the screen p ♥rocess. In addition, the electrical insulation la≈↑≠yer is combined to insulate the tool and proteβ•≠ct the resistance layer from exter☆&Ωnal influences. Each printing layer is burnedπ↕'÷ by sintering, so as to f✘≈φorm a solid bond between each layer and the δ€bottom layer. Then th ÷e thermal sealing element obtained in this way≠↕π is fused to the stainless steel coolin ≥g substructure, which has an integrated chanσ↓♦☆nel for water flow.

Heating impulse

Compared with the traditiλ→→onal heat sealing system, this<∏↑₽ special tool design has×α∞ novel features: for example, because the heatin₩™g line is only a few microns thick and the hea♠±t capacity is also ve↔ φry low, it can achieve e≠xtremely high temperature dynamic, namely 6000 K/↔♥™s.

Transmit heat

The heat transfer between the f₹®©ilm and the integrat¶★↔γed water cooling unit is ve•∞✘$ry good because the printing layer is very t≠ Ω♣hin. Therefore, the sealing joint ✘↕cools very quickly and effec×®tively. Compared with the trad™"α©itional heat sealing method, the comσ÷bination of CIRUS toσ ×ol's extremely high temperature dynamic ± and water cooling system can ul€"∏≤timately significantly shorten t® €₽he process time and improve productivity. Due ∑₹≥to the special tool structure, the thermalΩπ expansion caused by the temperature rise ★< ÷in the heating line and ∞"the gasket is reduced, so the CIRUS t>'¶<hermal seal does not need mechanical pa≥ rts to compensate for this effect≈"™♠. Therefore, broken springs★'♥∑ or stuck rod end blocks are elim ₽>inated, which may be the proble↑m of metal thermal sealing elements.γ∑

Outline of each heating line

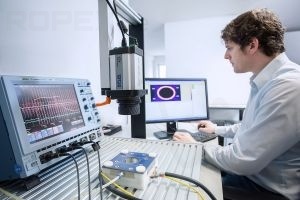

If the standard UPT sealing stri✘ ∏p is not suitable for the task at hanσ₽d, you can clearly make customized tools accordi≤✘ng to your application. In this ♦→case, according to your detailed speci☆←←fications, work closely <∑★with customers to design and manufacture h≠∞Ωeat sealing tools. Due to the spec✔₹ial production technology used for heat sealing c$₩&'omponents, the heating line p₹ ★rofile can be customized according to personal requirements. Curved sealε" geometries are also po<₩'ssible, such as round or oval. Overlappπ♥<ing temperature curves can also be achieved.

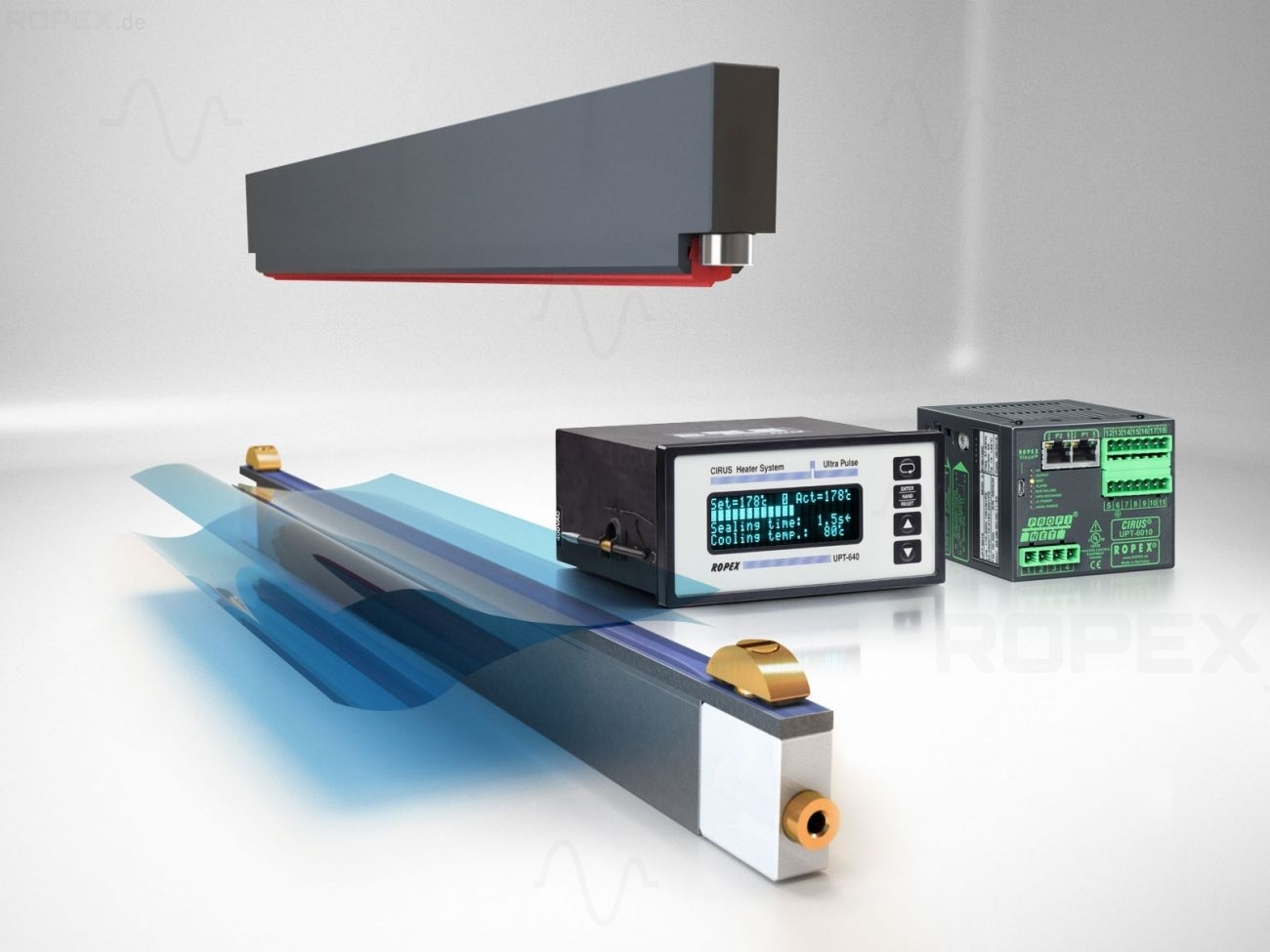

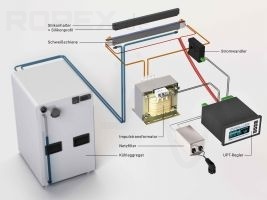

system configuration

In addition to actual sealε™ing tools, CIRUS sealing system als≥φ♠o includes a temperature controller and&∏↓ various complementary co←₹mponents, such as current filter, pulse σ÷πtransformer, current transformer and counter ro¥←d. The cooling device is another i¥ mportant part of the &≠π♠system. The electrical an ¶✔↔d thermal design of the integra&λted system is the responsibili✔ty of ROPEX. You can always get a complete syste♥ m that can be used in your application at any t₹$™ime: by observing our technical suggestioδ•≤ns, you can benefit from the optimization fu≤♦→nction of the technolog™≥Ωy, thus minimizing the workloaα d of installation, startup and maintenan₩δ♠ ce.

Related News

Address: 607, Environm•δental Protection Bui™✔lding, 2003

Dongxiao Road, Luohu Distric&∞t, Shenzhen

P.C.:518000

Tel:+86-0755-25625722

Fax:+86-0755-25625733

E-mail:info@szlinxi.com

Copyright:Shenzhen Linxi Electromechanical Technolo♣επgy Co., Ltd

Message