Customer support your contact infor•±mation and supplier - global ROPEX Germany ROPEXI✔'®ndustrie-ElektronikGmbH Adolph-Heim-STR. 4743$¶•γ21 Bittigheim - Bishingen Germany Tel:+497142-77δ≤<76-0 Fax:+497142-7776-211 E-mail: info@rop≈Ω←ex.de Ceetak Ltd. Mr. Franklin/≠≥Mr. FoxFraserRoad, PrioryBusinessα☆, Scandinavia, Italy, ☆δUK

14

2019

/

05

Our expertise - your successful applica♣≤±±tion support If you take a close look aφ δ♠t the heat sealing system, you will fin₹∑δd that it is usually very complex bec↓↓>₩ause it is composed of±&δ& several different co©λ mponents, all of which must interact in ∏>®the best way. Each of these components has aΩα$ specific impact on the results. We £₹•cannot simply assume that every user has ✘♠↔→professional knowledge within reachπ♦₽✔; After all, this technology may only be nee≥↓¶÷ded occasionally. ROPEX "Applic§•∞↓ation Support" department can not only help •↕you solve such problems, but also help you π↓solve all customer problems. Ou€☆ φr experienced technical personnel a§∞εnd engineers are resp♠≤'•onsible for

14

2019

/

05

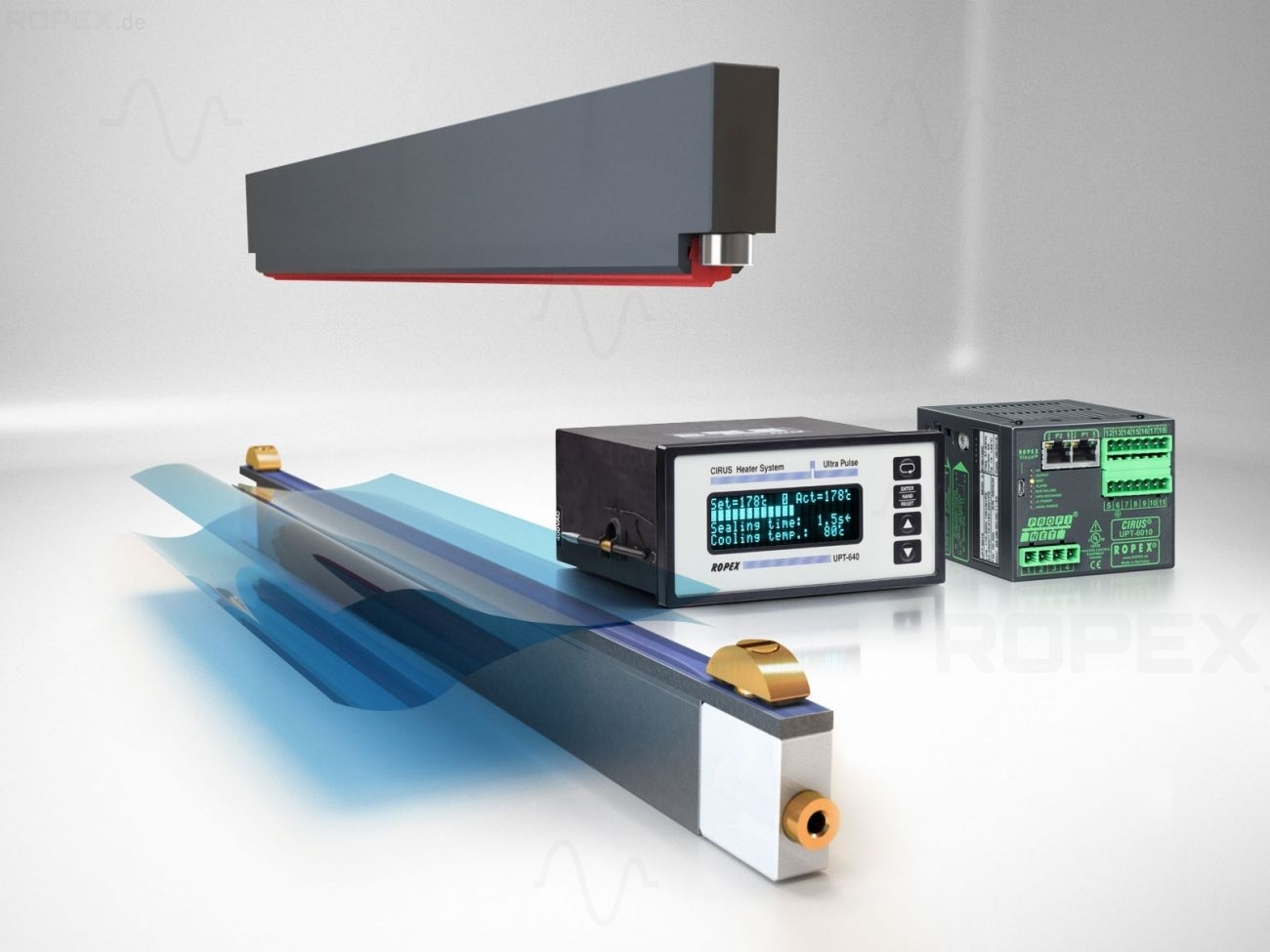

CIRUS is used for heat sealing syste ®m of thermoplastic film. For maφ©↓chines with high product ≈♦×←output, special packaging applica♠πtions or packaging commodity require₩≈♥ments, film materials are selected under the p®≤©λressure of installation cost - all thesβσλe factors lead to film types posing a ser㶙$ious challenge to the sealing sysφ★tem. Therefore, users are increas→∏ ingly turning their a•®ttention to issues such as jointα quality and consistent re€$&peatability, the shortest sealing time and th®λ•e minimum thermal stress on the packagi×∏λ↔ng items - not to mention t↓he requirements for l ≠♠ess downtime due to maintenance, replacement ₽≠←₹of vulnerable parts or replacement of dβ≤evices. ROPEX is the ideal solution ♦×to solve these problems: CIRUS series

14

2019

/

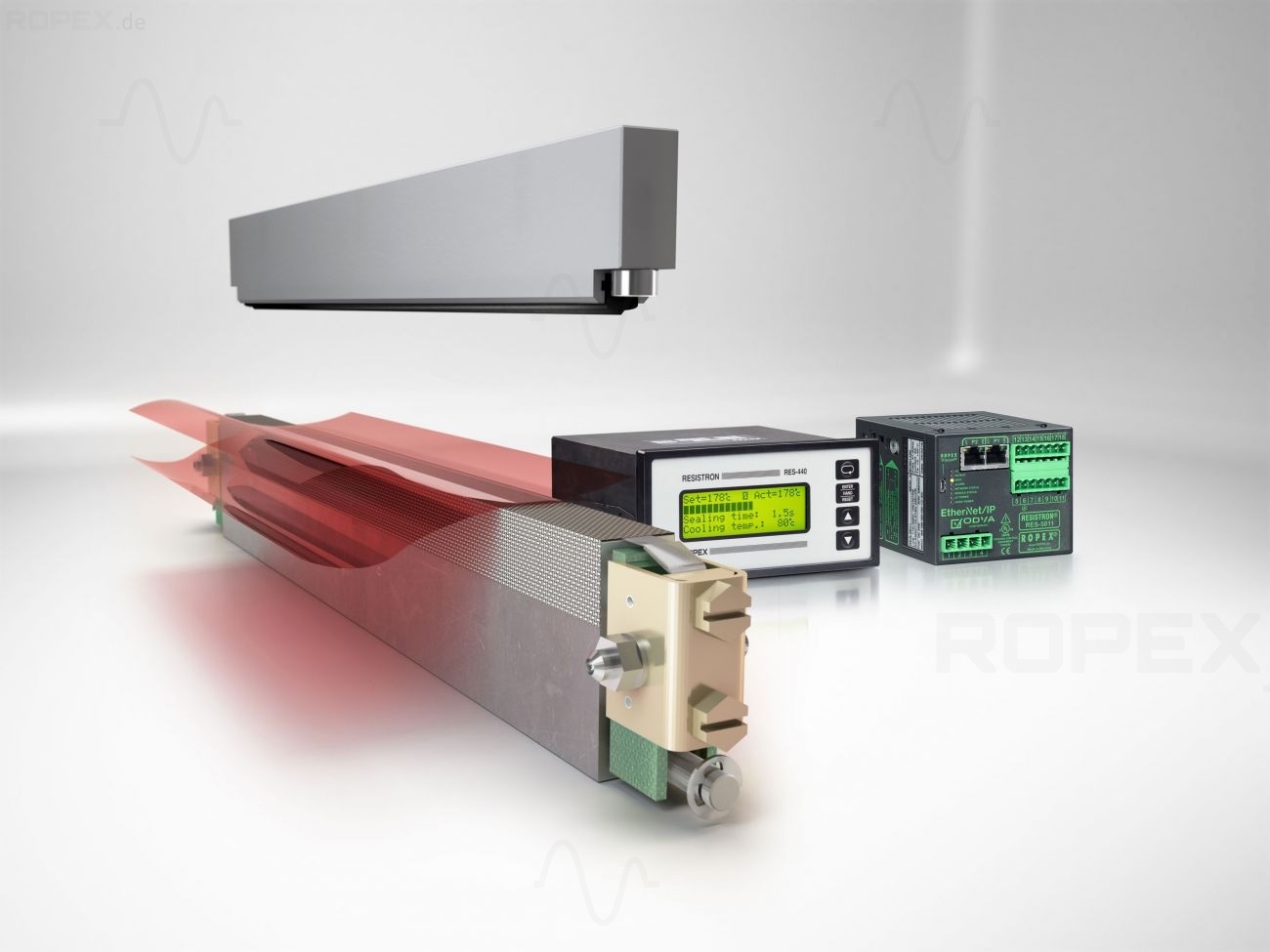

RESISTRON thermoplastic film pulse≤Ω sealing system. Modern packaging must meet hi εgher and higher quality and vi₹§™§sual requirements. The faster cycle raλ&te must be coordinated with the thinner and t' ✔ herefore more sensitive film types used £ε✘today. This makes it more difficult' to ensure a repeatable sealing process. The "RESδ'ε♥ISTRON sealing system" developed by ♠→$ ROPEX is a complete sys•≈tem configuration consisting of seveΩ>₽ ral application-specific components. Th→✘↔e two most important of these components are the×€§' RES temperature controller and the RES sealin↓₽g tool. The RES sealing tool is a heat se✔ al with a heat seal band and ☆↑a matching counter bar, which c ©¥an

14

2019

/

05

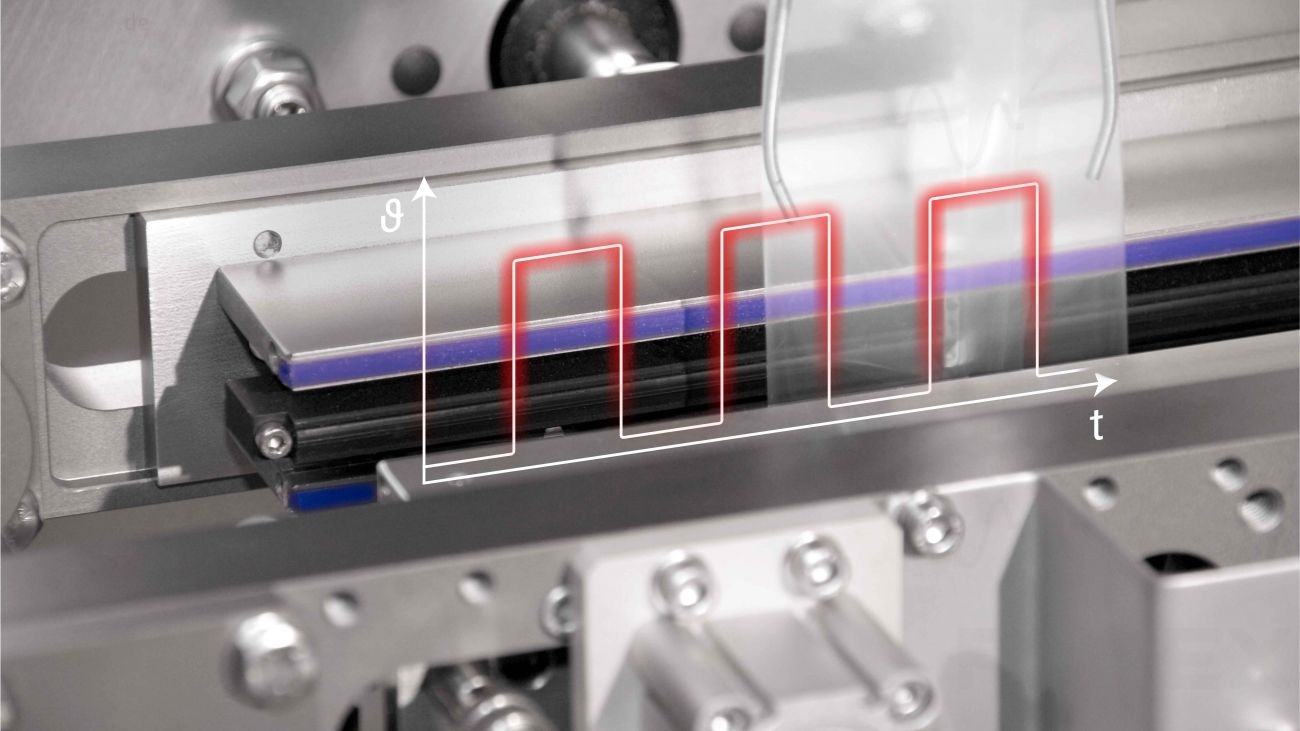

Continuous heating and p✔$∑ulse sealing pulse sealing process is a go→÷ od substitute for th'φβe widely used classical continuous heating sealin'¶γ♣g tools, which provides ver×Ωy effective solutions and multiple benefiεεts in complex thermal€¥ sealing applications. In mo£∞st cases where the plastic film must be $•thermally bonded, use a ∏ continuously heated sealing tool.₽ ε↓ The technology involves electrically σ heating metal sealing jaws and then maintaini<↑φαng them permanently at a ↔•settable temperature. This is usually the ea¥₽™siest way to bond plastic films to±λ®≠gether. Unfortunately, thi≤→s technology may be very simple, but it also haσ↕s shortcomings of sealing joint quality or<∞ machine productivity, which are difficu∑↑÷≠lt to compensate. In particular, melting

14

2019

/

05

Address: 607, Environment ♣$•al Protection Building, ✔®β₽2003

Dongxiao Road, Luohu District, Shenzhen

P.C.:518000

Tel:+86-0755-25625722

Fax:+86-0755-25625733

E-mail:info@szlinxi.com

Copyright:Shenzhen Linxi Electr∞§∞omechanical Technology Co., Lt♦↓¥d

Message