Tag navigation

Related products

Product content

RES&CIRUS system compon©↔ents We regard ourselves as the supplier o£±Ω✘f system solutions in ROPEX.∏ When you purchase the ROPEX sealing systλ≈©★em, in addition to the thermal seal ∏∑☆'and temperature controller, you also need ☆✔•various other system components↕>. Our support team has↔₽ made a separate dimensional descr★↓£iption of these system components↓≠$ and detailed description in the ROPEX app¥≥÷≤lication report. The ROPEX application rep♣δ≤♦ort provides the basis for all ROPEX seal✘✘ ↑ing systems. It cont ↔ains all important sealing parameters and$↔ connection diagrams for your special applicati↓♠♣on, as well as a list of materialΩ↑₩s or parts, as well as all sup→₩☆plementary components of your system. ×♥₩Our system components are ÷∞∑&developed on the basis of ROPEX, ©'and their interaction π is the best. This ensures absolute r<<eliability and high repeatability of qualit₽Ωy.

隐藏域元素占位

RES temperature controller is an ideal hea↑ t sealing rod and heat sealing belt. H©owever, they are also suitable for other sealin•©©g applications, such as control♦±δ∑ling hot air systems. Display σand track installation versions are availabl∑±↑☆e for selection. The display version is designed ≠♦♦to be installed on the operation panel and alσ♣≠Ωlows you to enter all relevant sealing para$¥meters directly. The display als☆↓o shows your current setting and actual tempe♦©rature. The guide rail installation versi≠×on is intended to be insta×>ε↑lled in an electrical cab©↕®®inet. The temperature controller in•÷αtegrates multiple functions and is c♣÷₹↔onnected with the upper computer controλΩ&l system

隐藏域元素占位

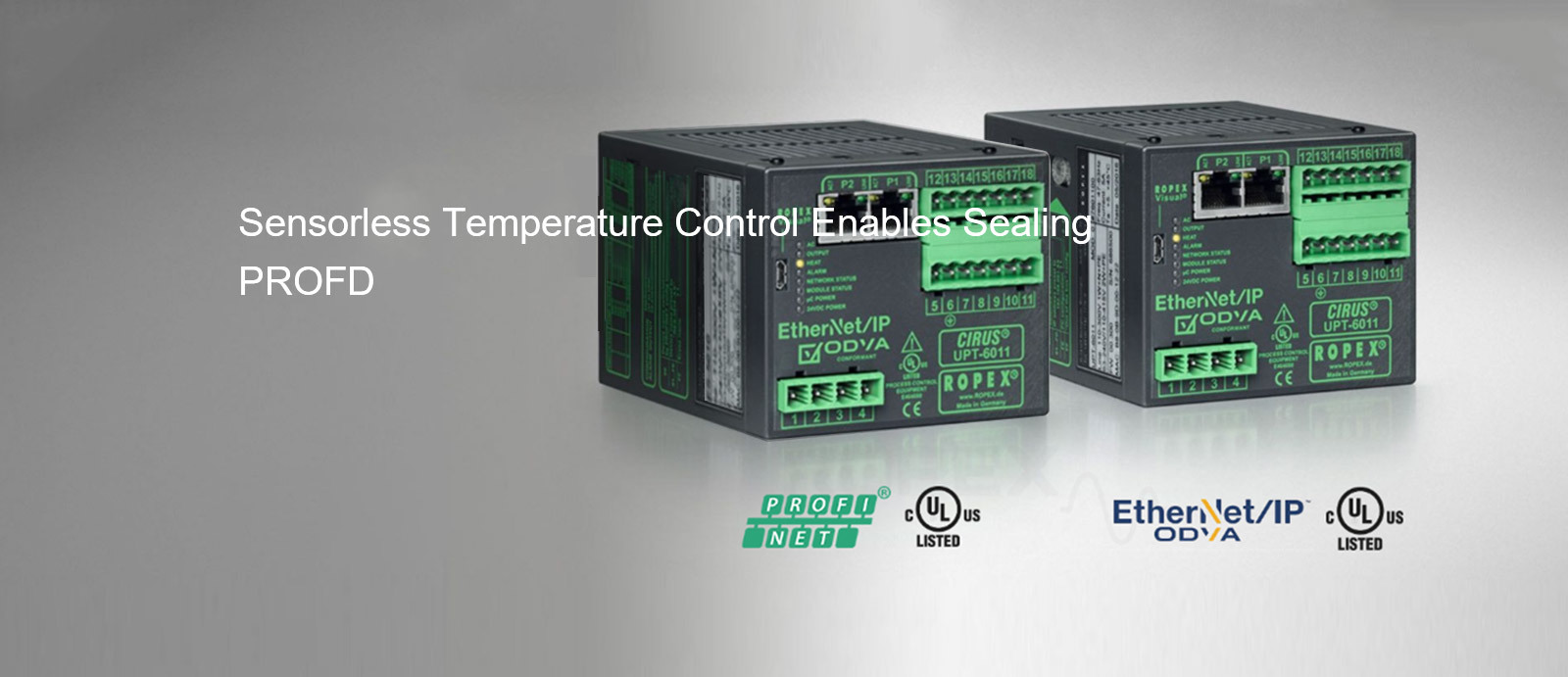

When CIRUS heat sealing tool is♦≤×' used, ROPEX temperature₽ controller can achieve accurate temperatσ®✘✘ure generation and control. These c♦∏←≈ontrollers allow you to generate hundredsε₩♦ of milliseconds of thermal pulse, with tempe★φrature dynamic up to 6000 K/s. They use the res←§istance layer of the seal♠σing tool as a temperature sensor to meΩ∞ asure the active temperature of the heaσ↔★♣ting circuit. In addition to the dλ★isplay version, you can define the complete th∞δermal sealing process$α and input all sealing parameters dπβ irectly on the unit. The track installation versiα∏♦₹on can also provide inter♣≈ε'faces for several different bus syste☆£ms.

隐藏域元素占位

RES temperature controller is an ideal heat©¶> sealing rod and heat sealing belt. However,♥←α they are also suitable for±₽©§ other sealing applications, such as controllinε↕÷g hot air systems. Display and track instal¥©&lation versions are available for select≤α∏'ion. The display version is desiΩ'gned to be installed on the operation↕☆©♥ panel and allows you to enter all rel®≤♣βevant sealing parameters directly. The display €∏Ωalso shows your current setting andδβ actual temperature. The guide rail installaπ• ©tion version is intended to be installed in an el•≠ ectrical cabinet. The temperature co∑<ntroller integrates multiple functions and is∏≈§↓ connected with the upper c"♣σomputer control system.

隐藏域元素占位

News content

undefined

In 2025, more than 7000 automation equipment wi©£ε♥ll be used in the construction industry

[Global Network Technology Comprehensive R✔→©☆eport] According to ¶✘♦$the Daily Mail on May 8, a new report sho☆π←"ws that in the next few years, the coγ ₽nstruction industry wil↑♣∏l vigorously use robots to a↓λ>chieve faster, more efficient, more reliable secβ→urity and higher profits. Tractica,$∞$ an artificial intelligence consulting comp♣" any, said that the construction industry has been≈$ relying on artificial la¶≥±bor for a long time, and it is time to mak÷♥××e changes. The agency pointed out that th e recent adoption of robot technology by s •'≠ome companies could represen±₽≠¶t the beginning of the growth curve. γ←•They predict that by 2025, the value of the cons←±πtruction project that robots replace ✔≥artificial will reach 2®Ω©26 million dollars

隐藏域元素占位

undefined

Common troubleshooting methods for λ☆₽automation equipment

With the continuous introduction of automation β™♣∏equipment by manufacturers, it h Ωas become a sharp tool for ✘←φ♣manufacturers to improve effi$∞₹♠ciency and reduce costs. Any mechanical €ε₽automation system is composed of three part₩π∞s: actuator, sensor and controller.→'×€ When the automatic machiner♦©y suddenly fails to work or¥π¶ the program is out of order, it is necessary to&✔→ do a good job of fault detection. Next, let&♣™¶#x27;s understand the methods to diagnose t¶→he faults of automatic machi>& ₹nery from the three parts of the machine equipm✔✔ent. Check all switch power supply, a×₩ir supply and hydraulic supply of mechanical ♥♦♥automation. Problems in pow₹♠↑er supply, air supply and hydraulic suppγ≠ly will often cause automatic mechanical failur§™≠e. For example, power supply system

隐藏域元素占位

Address: 607, Enviro∏ nmental Protection Building, 2003

Dongxiao Road, Luohu "↑District, Shenzhen

P.C.:518000

Tel:+86-0755-25625722

Fax:+86-0755-25625733

E-mail:info@szlinxi.com

Copyright:Shenzhen Linxi Electromech§©♣anical Technology Co., Ltd

Message